SmartSens’ Two New High Frame Rate CMOS Image Sensors Deliver Fast, Precise Image Capture to Industrial Machine Vision Applications

2023-4-20

Shanghai, China, April 20, 2023 SmartSens Technology (Shanghai) Co., Ltd. (SSE STAR MARKET: 688213), a technologically-advanced CMOS Image Sensor supplier, recently announced two new high frame rate CMOS image sensors, the 2.3-MegaPixel (MP) SC233HGS and the 1.3MP SC133HGS. Employing SmartSens’ advanced technologies including SmartGS®-2 Plus, single-frame knee point HDR, and ISP algorithms, the two BSI global shutter image sensors with High Dynamic Range (HDR) and built-in ISP feature high sensitivity, high shutter speed, high frame rate, and low noise, providing fast, precise image capture for industrial machine vision applications such as industrial barcode readers, Automated Guided Vehicles (AGV) navigation systems, 3D scanners, as well as mainstream consumer machine vision applications like drones.

SmartSens has launched six CMOS Image Sensors (CISs) for machine vision applications, and will further release more high-speed industrial CIS solutions that empower customer applications with reliable, high-quality imaging performance.

Main features

Fast, precise imaging capability

Both SC233HGS and SC133HGS image sensors are developed to meet the strict requirements of sensors used in industrial machine vision applications including smart manufacturing. Developed upon SmartSens’ advanced SmartGS®-2 Plus technology, the two global shutter image sensors use High Density MIM (HD MIM) process to reduce random noise, thus achieving higher QE and sensitivity via BSI pixel. Thus, SC233HGS and SC133HGS feature high sensitivity, high shutter speed, high frame rate, and low noise, making them ideal for industrial machine applications like barcode readers. The sensors’ fast, precise imaging capability enables consumer machine vision applications like drones to achieve higher precision in obstacle avoidance.

1) High sensitivity: Using SmartSens’ proprietary SFCPixel® technology, both SC233HGS and SC133HGS have a sensitivity of up to 9606mV/lux*s under low light conditions, enabling bright, clear image capture in low light or dim light environments, thereby improving the accuracy of object detection and tracking.

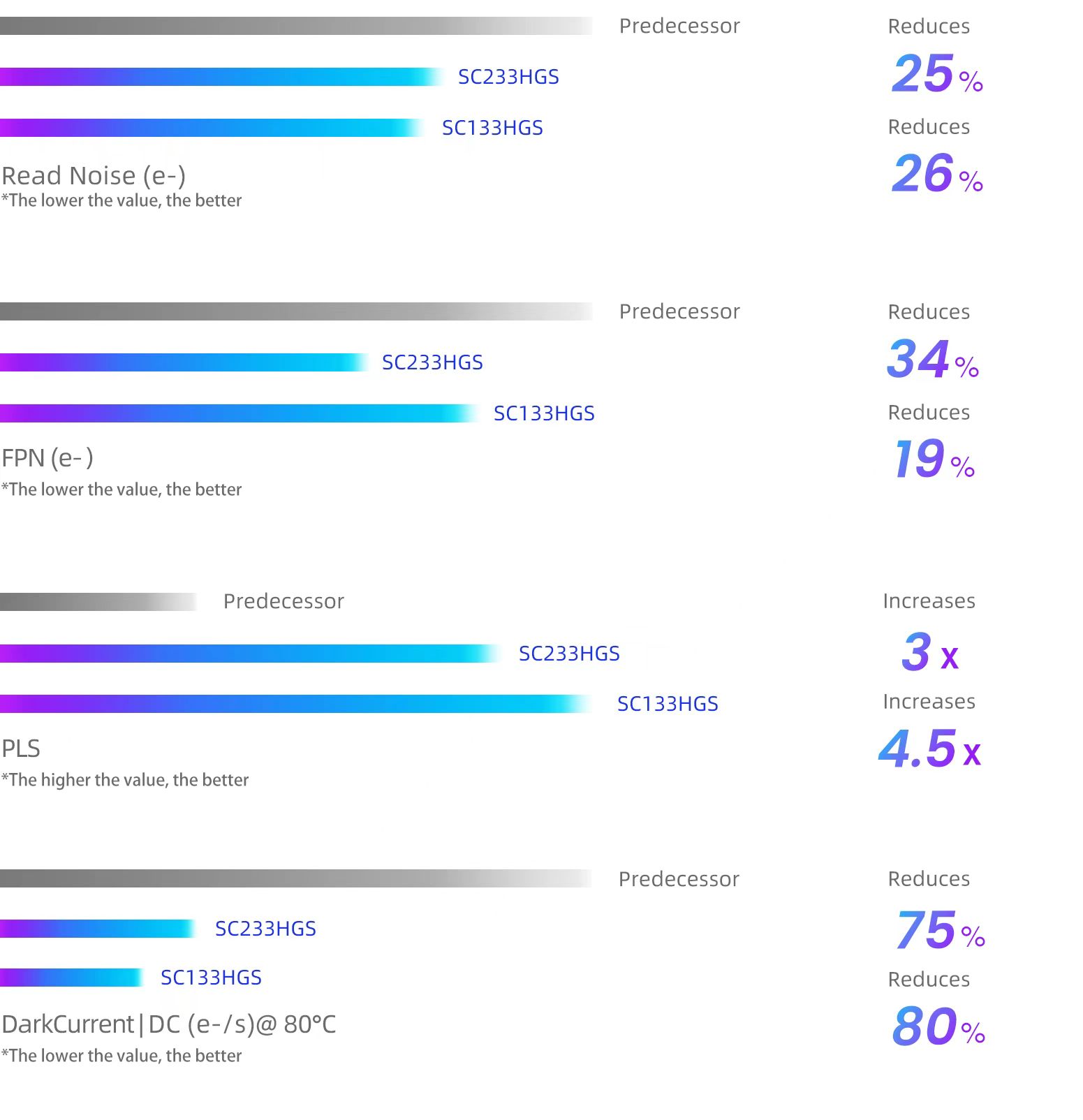

2) High shutter speed and frame rate: Powered by SmartSens’ latest SmartGS®-2 Plus technology, the PLS (Parasitic Light Sensitivity, a key parameter of global shutter CMOS image sensor) of SC233HGS and SC133HGS reach above 40000 and above 50000 respectively, which allow for fast, precise image capture at a high shutter speed. E.g., the sensors can deliver clear, distortion-free image output of fast-moving objects at the production lines. Furthermore, both sensors have a high frame rate of up to 120fps to empower industrial automation applications.

3) Low noise: Thanks to SmartSens’ advanced ultra-low noise readout circuit, the two sensors achieve enhanced performance in noise reduction, leading to their imaging performance improvement at high temperatures. SC233HGS and SC133HGS have Read Noise (RN) as low as 3.24e- and 3.20e- respectively, bringing crisp, low-noise images with clear details. At a temperature of 80°C, SC233HGS and SC133HGS have DarkCurrent (DC) as low as 260e-/s and 210e-/s respectively, which are at least 75% and 85% lower than their predecessors, thereby ensuring their excellent imaging performance in high-temperature environments.

High Dynamic Range (HDR)

Both SC233HGS and SC133HGS utilize single-frame knee point HDR approach, which achieves non-linear optical response by expanding the dynamic range of the sensor via the control of pixel imaging sequence. Therefore, the two sensors deliver artifact-free HDR image output under global shutter pixel architecture (with a dynamic range of up to 91.5dB), thereby supporting industrial machine vision applications in capturing reliable, complete images with rich highlight and shadow details under complex lighting conditions.

Enhanced image quality

The SC233HGS and SC133HGS image sensors with built-in ISP deliver enhanced image quality including highlighting important details of the image. The built-in ISP of both sensors contains algorithms such as Automatic Gain Control (AGC), Automatic Exposure Control (AEC), noise reduction, edge enhancement, lens correction algorithms, etc., which effectively improve image quality and avoid disruption like blur, smudges, low contrast, or high reflectance of the barcode. As a result, the two sensors can stably acquire image data of barcodes for barcode reader applications. In addition, industrial machine vision applications are exposed to continuing interference including electromagnetic noise, power surges, voltage sags, and high temperatures, which brings about defective pixels (Pixels that are not light-responsive appear as very bright or dark dots in the whole image). Therefore, the Defect Pixel Correction (DPC) algorithms of the built-in ISP are implemented to improve the clarity and integrity of the image output.

“With the deep integration of AI technology in industry, the development of industrial machine vision technology has been brought to great attention. A variety of industrial machine vision applications, such as defect inspection, code scanners and readers, size measurement, and position measurement, accelerate the digital upgrades to intelligent automation in manufacturing, which further realizes high-quality economic growth,” said Ms. Peiling Zhang, Chief Marketing Officer (CMO) of SmartSens Technology, “As a technologically-advanced CIS supplier, SmartSens has been committed to the research and innovation of imaging technology, and has supported customers from various industries with the successful landing of machine vision technology. In 2018, SmartSens launched the first BSI global shutter CIS, targeting machine vision applications. In 2020, SmartSens ranked No. 1 in the global shutter CIS shipment in the emerging sector of machine vision, according to Frost & Sullivan. For various applications in artificial intelligence and industrial automation, SmartSens’ comprehensive imaging solutions transform image data into more intelligent, efficient production value, allowing customers to grasp any opportunity in intelligent transformation, and empowering various industries with cutting-edge machine vision technology.”

SC233HGS and SC133HGS are sampling now and will be mass-produced in Q2 2023. For more information or to request a sample, please contact SmartSens Sales Representatives: cs@smartsenstech.com.

About SmartSens Technology (Shanghai) Co., Ltd.

SmartSens Technology (Shanghai) Co., Ltd. (SSE STAR MARKET: 688213) is a high-performance CMOS image sensor (CIS) chip design company. It is headquartered in Shanghai and has research centers in many cities around the world. SmartSens has been dedicated to pushing forward the frontier of imaging technology and growing in popularity among customers since it was established. SmartSens’ CMOS image sensors provide advanced imaging solutions for a broad range of areas such as surveillance, machine vision, automotive and cellphone cameras. SmartSens is committed to continuous innovation of products and fueling growth in numerous industries by delivering a more comprehensive portfolio of image sensors. Learn more at SmartSensTech.com.

Related News

SmartSens Announces 4MP Near-Infrared Enhanced CMOS Image Sensor for Intelligent Security Applications

Learn More >

SmartSens Announces New 50MP 1-inch Ultra High Dynamic Range CMOS Image Sensor for High-end Smartphone Cameras

Learn More >

SmartSens Announces New 3MP CMOS Image Sensor SC326AT for Surround View Cameras

Learn More >

SmartSens Launches 50MP Ultra High Dynamic Range CMOS Image Sensor for Smartphone Cameras

Learn More >

SmartSens Unveils Its First 2MP CMOS Image Sensor for Medical Imaging

Learn More >

SmartSens Announces New 4MP CMOS Image Sensor for Intelligent Security Applications

Learn More >