SmartSens Launches 0.3MP High Frame Rate CMOS Image Sensor for Industrial Machine Vision Cameras

2024-1-25

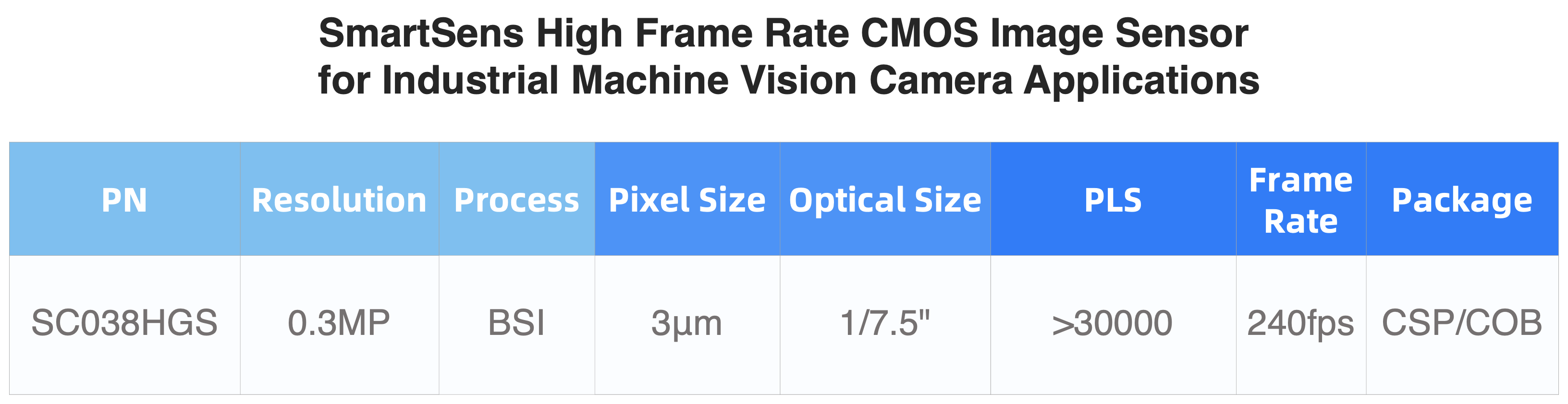

Shanghai, China, January 25, 2024 SmartSens Technology (Shanghai) Co., Ltd. (SSE STAR MARKET: 688213), a technologically advanced CMOS image sensor supplier, recently announced SC038HGS, the 0.3-MegaPixel (MP) high frame rate CMOS Image Sensor (CIS) for industrial machine vision cameras. Incorporating SmartSens' advanced SmartGS™-2 Plus technology and excellent circuit design, the BSI global shutter image sensor combines superior performance in high sensitivity, low noise, high frame rate, and low power consumption, enabling diverse applications such as industrial machine vision cameras, drones/sweeper obstacle avoidance systems, and AR/VR 6DoF systems.

Main features

SmartGS™-2 Plus technology

SC038HGS utilizes SmartGS™-2 Plus technology and BSI global shutter structure design, bringing better Quantum Efficiency (QE) and higher Full Well Capacity (FWC). And it also adopts High Density MIM (HD MIM) process, which largely reduces random noise and improves image quality.

High sensitivity

With advanced SmartGS™-2 Plus technology, the peak QE and FWC of SC038HGS are up to 90% and 12.4ke- respectively, which helps industrial machine vision cameras to accurately inspect and measure targets in low-light industrial scenes.

Low noise

Employing SmartSens' ultra-low noise readout circuit, SC038HGS achieves low noise and improves imaging performance at high temperatures. Its DarkCurrent (DC) is low to 247e-/s at 80°C, resulting in clean, detailed and low-noise images.

Low power consumption

SC038HGS’ power consumption is as low as 48.6mW, which further extends the battery life of applications like drone/sweeper obstacle avoidance systems and AR/VR 6DoF systems.

High frame rate

Applying advanced SmartGS™-2 Plus technology and high frame rate design, SC038HGS has excellent shutter efficiency (PLS>30000) and supports high frame rate of 240fps, which significantly improves the imaging speed and stability, thus facilitating the productivity and precision of products in industrial machine vision camera applications.

Multiple interfaces

SC038HGS supports MIPI D-PHY, LVDS and DVP interfaces. These interfaces provide flexibility for applications like drone/sweeper obstacle avoidance systems, AR/VR 6DoF systems, etc., which contributes to meet the demand in image stability and cost-effectiveness, enabling devices to operate better in high-speed scenes.

SC038HGS is sampling now and will be mass-produced in Q2 2024. For more information or to request a sample, please contact SmartSens Sales Representatives: cs@smartsenstech.com

About SmartSens Technology (Shanghai) Co., Ltd.

SmartSens Technology (Shanghai) Co., Ltd. (SSE STAR MARKET: 688213) is a high-performance CMOS image sensor (CIS) chip design company. It is headquartered in Shanghai and has research centers in many cities around the world. SmartSens has been dedicated to pushing forward the frontier of imaging technology and growing in popularity among customers since it was established. SmartSens’ CMOS image sensors provide advanced imaging solutions for a broad range of areas such as surveillance, machine vision, automotive and cellphone cameras. SmartSens is committed to continuous innovation of products and fueling growth in numerous industries by delivering a more comprehensive portfolio of image sensors. Learn more at SmartSensTech.com.

Related News

SmartSens Announces New 50MP 1-inch Ultra High Dynamic Range CMOS Image Sensor for High-end Smartphone Cameras

Learn More>SmartSens Announces New 3MP CMOS Image Sensor SC326AT for Surround View Cameras

Learn More>SmartSens Launches 50MP Ultra High Dynamic Range CMOS Image Sensor for Smartphone Cameras

Learn More>SmartSens Announces New 4MP CMOS Image Sensor for Intelligent Security Applications

Learn More>SmartSens Announces New 12MP CMOS Image Sensor for AI Glasses Camera Applications

Learn More>SmartSens Announces New 3MP CMOS Image Sensor SC360AT for ADAS Cameras

Learn More>